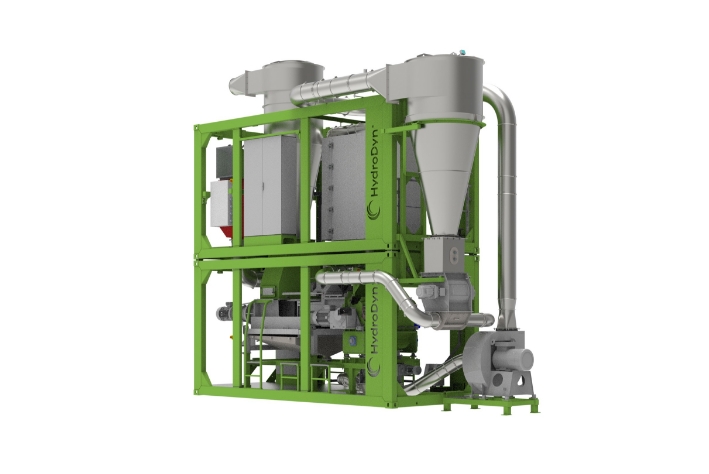

FlexDryer TWO

FlexDryer TWO

The FlexDryer TWO uses a unique combination of mechanics and heat to optimise the drying of film. Between the mechanical and thermal drying processes, the material is loosened, and then also mixed with a strong airflow during transport.

Thanks to controlled mechanical drying with an adjustable press, the FlexDryer TWO guarantees precise drying of your film without affecting the integrity of the material. Subsequent booster drying can then be used to achieve drying values from as low as 1 per cent up to a maximum of 2 per cent – with minimal energy consumption.

These low residual moisture levels not only reduce gel formation, but also significantly reduce energy consumption in downstream processes. The integrated discharge of separated process water and used air keeps the drying process clean and efficient. An AeroSeparator can be added to the FlexDryer TWO to enable the purification of PCR/household and agricultural film waste.

Request offer