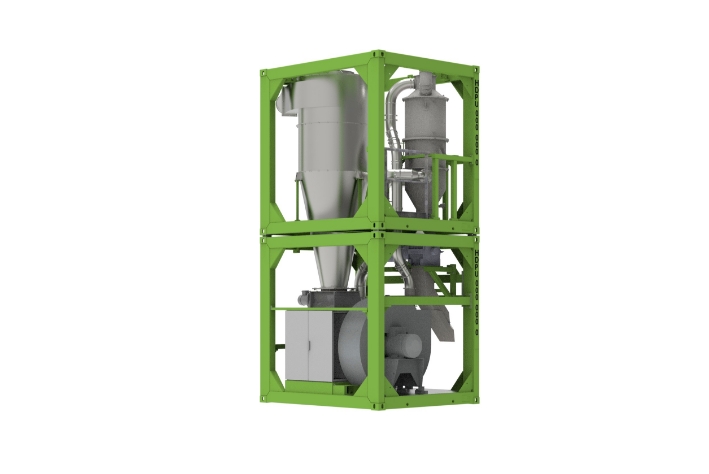

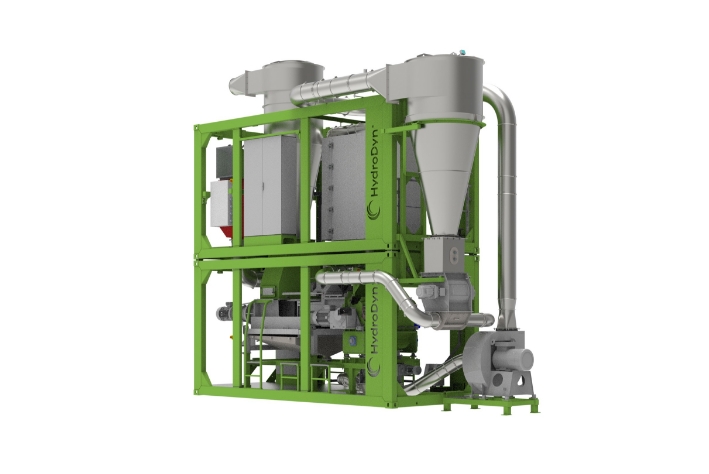

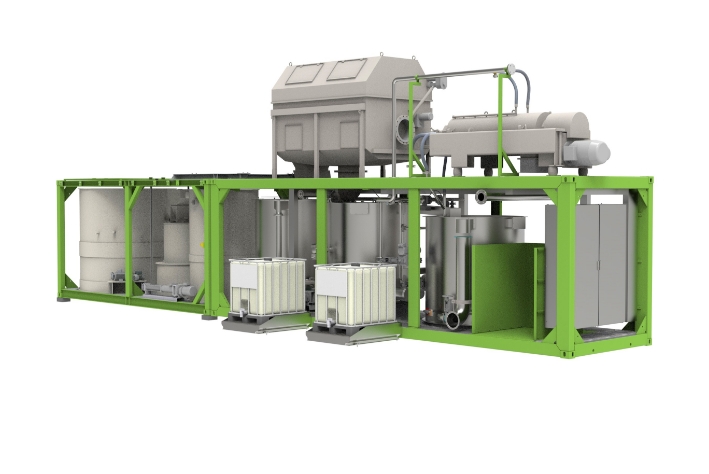

AeroSeparator TWO

AeroSeparator TWO

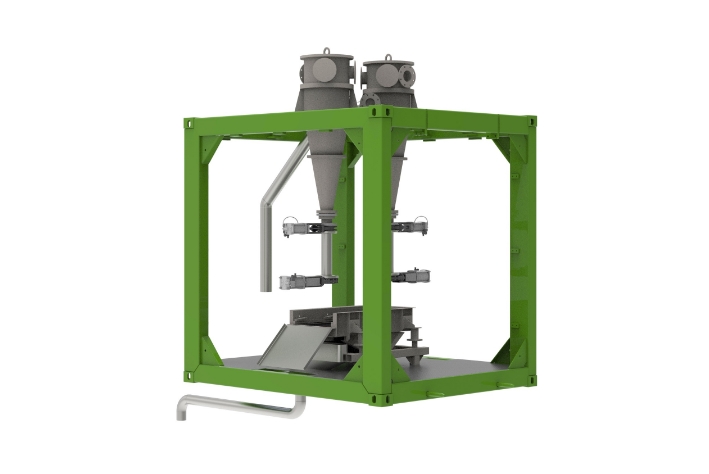

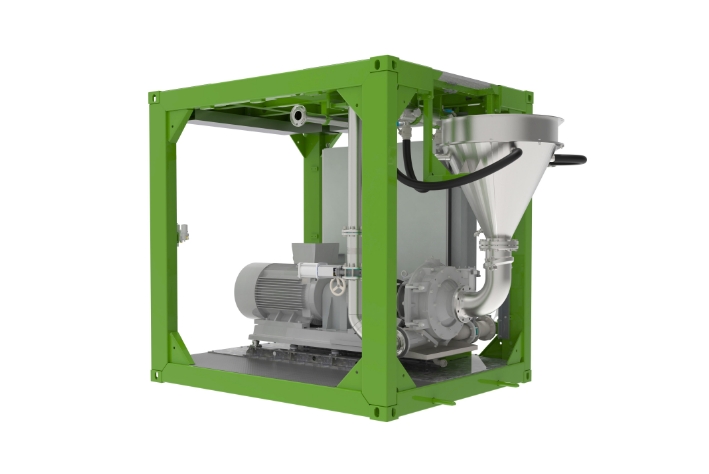

The AeroSeparator TWO is a classification process for the precise separation of 3D rigids and 2D flexibles – in order to recover high-quality materials.

Thanks to the principle of counterflow with low consistency, we achieve outstanding separation results, effectively separating rigid and flexible materials from one another. Our AeroSeparator also cleans the material flow by separating out impurities and dust, so you will always obtain high-quality recycled material.

Another aspect that sets our AeroSeparator TWO apart is its versatility. Not only can it separate laminated multilayers from individual layers in film, but it can also be enhanced with our BoosterDryer system for subsequent drying. For optimal drying processes.

Request offer